The lifecycle of an edge is to start fresh from the factory, and to then extend the life of that edge through maintenance sharpening until it is time for a full service sharpening again. Most people do not complete the lifecycle and continue to use maintenance sharpening long after its effectiveness is lost.

The reality is that each sharpening method is different and has its own impact on your knife. This article aims to identify. explain, and quickly compare guided systems to the usual methods of sharpening, and we shall see if guided systems are able to deliver the sharpest knives in the kitchen.

What Is A Guided Knife Sharpening System?

Guided sharpening systems, or guided sharpeners, are advanced sharpening devices that securely hold knives in a fixed position and sharpens the blades with repeatable precision and consistency every time. The user gets to choose and set the exact angle or angles they want for their knives. These systems have a wide selection of interchangeable custom sized sharpening stones and strops that fit into a stone holder, which is attached to a guide rod. The rod and stone are then used to sharpen at the determined angle, producing human error-free results every time.

Which type of sharpening are you doing?

There are 2 main types of sharpening: maintenance sharpening, and full service sharpening.

Maintenance sharpening is essentially touching up an edge to keep it cutting. The majority of sharpeners on the market are maintenance sharpeners. They are designed to work well in the short term, but they all ultimately distort the edge geometry to a point where they need resetting, or a full service sharpening. They simply do not have the cutting power to do any heavy abrasion. Some of the Maintenance sharpeners may have extended abilities, so we have used the (+) sign to indicate that in the next section.

Full service sharpening includes maintenance, but also means repairing chips, thinning blades, creating new bevel angles on (or profiling) knives. In other words, doing everything needed for sharpening and maintaining your knives. The major requirement of full service sharpening includes the ability to choose and set your own sharpening angles, and is even more versatile when there is more than one step or grit involved, such as a coarse, medium and fine grit.

The lifecycle of an edge is to start fresh after a full service sharpening, and to then extend the life of the edge through maintenance sharpening until it is time for a full service sharpening again. Most people do not complete the lifecycle and continue to use maintenance sharpening long after its effectiveness is lost.

Interestingly, however, all the sharpening methods are different and have their own impact on your knife. This blog explores different types of sharpening systems and discusses the best use of each sharpening method.

Continue reading as we explore the different types of sharpening methods and systems, among other methods.

The Primary Methods Of Knives Sharpening?

When looking for different ways to sharpen a knife, you might come across multiple ways to add an edge to your blade. However, experts at Jende Industries suggest that there are only three primary methods of knife sharpening:

- Grinding or Whetting: This is a very efficient and fast sharpening process used by many traditional knife sharpening professionals. As the name suggests, grinding (when done on a grinding wheel) or whetting ( when done on a whetstone) involves running your blade in the opposite direction of a grinding wheel or whetstone. When done correctly, it leaves behind a sharp, high-performance edge to your knife.

- Steeling: This is another traditional knife sharpening method involving honing steel. Under this sharpening method, users must run long honing steel at a given angle along their blade. When done accurately, this method adds a renewed sharpness to your blade.

- Stropping: Stropping is the most common method for knife sharpening in households today. This process is usually executed on a razor strop to remove the last imperfections from a cut. When running your knife at a given angle across the strap, you add a unique finish to the edge of your knife.

While these were some primary methods for ‘how to sharpen a knife,’ the list doesn’t end here. Over time, new and better methods came onto the market, removing the margin of error from knife sharpening and introducing us to a perfectly edged knife. You can read more on Do Knife Sharpeners Cause Damage to Your Blades?

Let’s learn more about these professional sharpening systems in the following sections.

Because users can secure the knife or determine the angle at which they’ll sharpen the blade, this knife sharpener system ensures structured sharpening. This way, guided sharpening systems give you a perfect edge whenever you sharpen your blade.

What are the usual sharpening methods?

Sharpening Steel – (maintenance sharpening)

A sharpening steel is often called a honing steel, and is a rod used to maintain your edges. They can be made of smooth steel, ceramic, or be diamond coated. In general, sharpening steels keep an edge sharp with quick touch ups as the blade dulls from use. We’ve all seen it on TV, and it’s a tried and true way to top-off and prolong your edge with minimal invasiveness and abrasion. You do need to learn good angle control when using the steel or you can prematurely round the edge. The sharpening steel won’t keep your knives sharp forever in most cases. Eventually, the blade will need to be reprofiled or reground and “reset” to the original angles.

Pull-Through Sharpeners – (maintenance sharpening +)

Pull-through sharpeners feature two small abrasive bars or rods in a V shape that are always the same angle, and work more precisely than sharpening steels to maintain your edges between actual sharpening sessions. Depending on the number of sharpening slots, it can do more to prolong the edge of your knife. Technique is pretty easy on a pull-through sharpener, but the knife will need a full-on sharpening session once the blade conforms to the preset angles.

Electric Knife Sharpener – (maintenance sharpening +)

Electric knife sharpeners are handy tools that take pull through sharpeners to the next level by adding speed and often even more refinement. These can save you significant time when maintaining and touching up your kitchen knives. As with the pull-through, the knife will need a full-on sharpening session once the blade conforms to the preset angles. Proper technique is also recommended to keep from deforming the overall blade shape over time. With speed comes responsibility!

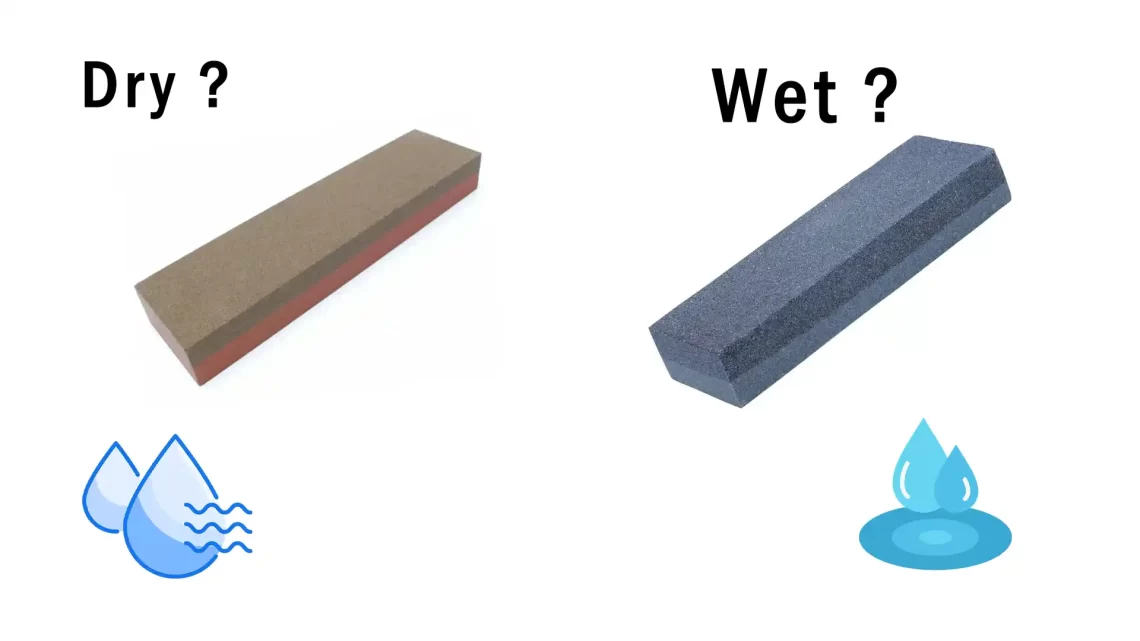

Knife Sharpening Stone – (maintenance & full service sharpening)

Next, we have the sharpening stone, or whetstone. It is considered a universal method of sharpening. Sharpening stones are able to do regular maintenance like the sharpening steels and pull-through sharpeners, but because they are available in many grits, they can do actual full-on sharpening and repairs as well. Stones do require learning the most technique in order to hold the knife angles steady while sharpening and often need a dedicated area to work in.

Guided Sharpening systems – (maintenance & full service sharpening)

Guided sharpening systems have removed many of the technique problems associated with sharpening by often clamping the blades in a fixed position, and by allowing the highest levels of precision out of all the methods. Even the most inexperienced sharpeners can sharpen successfully from the very first time. Like sharpening stones, guided sharpening systems are considered a universal method, and have a wide range of stones and grits available. It does take a little more investment and time to set up, but results are practically guaranteed.

These sharpeners work by running a knife through a rotating, miniature sharpening stones slot. Moreover, if you’re using updated models like the Jende Industries guided sharpener, you can sharpen your blade without any prior experience in skilled sharpening.

Best Use For Different Sharpening Methods

Regarding knife sharpening, be ready to get exploited with options! Different sharpening methods yield different results. Interestingly, there are better uses for other sharpening methods. Let’s check it out in our curated chart below:

| Knife Sharpening Method | Type of sharpener | Pros | Cons |

| Guided Knife Sharpening | Maintenance & Full Sharpening | -Easy to use out of the box -Can maintain and repair -Highest precision level -Wide range of grits available | -Investment required -Needs space to work -Not easily transportable |

| Knife Sharpening Stone | Maintenance & Full Sharpening | -Universal method of sharpening and maintaining knives -Fast and effective -Available in many grits | -Technique required -Can be messy -Not convenient to transport |

| Electric Knife Sharpener | Maintenance sharpening + | -Speedy edge maintenance -Longer results between sharpening sessions -Good results | -Requires electricity -Speed can cause damage |

| Pull-Through Sharpeners | Maintenance sharpening + | -Less technique required -Works well for maintenance -Inexpensive | -Only for maintenance -Limited refinement |

| Sharpening Steel | Maintenance sharpening | -Tried & True maintenance method -Least expensive -Quick to use | -Only for maintenance -One grit only -Technique required |

Technique, grits, ease of use, price, quality

Given the types of sharpeners available in the market, a section of buyers are often confused with their options. Besides, most consider using knife sharpeners from premier brands like JENDE JIGS for knives or Edge Pro.

But which brand offers the best sharpening systems? Let’s find out in a detailed comparison.

| Overview | Jende Jigs Knife Sharpener | Edge Pro Knife Sharpener |

| Build | All dishwasher-safe stainless design comes with a weatherproof construction for everyday operations. | All stainless steel knife sharpeners have a vacuum base to stick to different surfaces. |

| Sharpening Range | Sharpening range that can go beyond 10-26 degrees. | Comes with a sharpening range adjustable between 6-33 degrees. |

| Mount Style | JIGS mounts to sit over Acrylic Base or directly on a tabletop. | Comes with a vacuum-style mount to fit in different surfaces. |

| Output | 26″ (65cm) Sharpening Capability allows the system to handle 12″ chef knives and machetes. | Can sharpen blades that are up to 5 ¼” wide. |

Verdict: The Jende Jigs and Edge Pro sharpening systems show that both products are excellent for use. However, the Jende Jigs knife sharpener takes the credit from the Edge Pro knife sharpener in more than one aspect.

Conclusion: Guided Sharpening Systems CAN Do It All!

This brings us to the end of our blog on the different guided sharpening systems that add an edge to your knife. Looking at the different types of sharpening systems, it’s evident that guided sharpening systems are among the best options present in the market.

If you want a review on Wicked Edge Knife Sharpener system. Click this Jende Industries Canada article link.

6 thoughts on “Guided Knife Sharpening System”