Choosing Sharpening Stones: A Quick Guide

When it comes to sharpening tools and knives, selecting the right sharpening stone material can make a significant difference in achieving the desired sharpness and edge quality. Among the most common types of sharpening stones are water stones, diamond stones, and oil stones. Each type offers distinct advantages suited to different sharpening needs. Let’s delve into the disparities between these materials.

Water Stones

Water stones have gained popularity owing to their exceptional performance benefits. Predominantly manufactured from aluminum oxide abrasive material, water stones are distinguishable from oil stones due to the binder used to hold the abrasives together. This softer binder in water stones promotes faster cutting, facilitated by the replacement of worn abrasive material with fresh sharp particles.

One of the clearest advantages of water stones is their rapid cutting ability. Moreover, they boast a broader range of grits compared to other stones, spanning from coarse grits like 120 to ultra-fine options exceeding 8000 grits. Additionally, water serves as a convenient and accessible medium for cleaning the stone, effectively removing metal particles generated during sharpening.

However, the softness of water stones presents a downside—regular flattening becomes necessary as the stone wears down. Thus, owning a flattening stone alongside a water stone is highly recommended to maintain optimal performance.

Diamond Stones

Diamond stones or Diamond Sharpening Stones feature industrial diamonds bonded to a metal surface, making them the hardest abrasive material available for sharpening. They come in various sizes, shapes, and grits, offering versatility in sharpening different tools and knives.

Two primary types of diamond sharpening stones exist: those with interrupted diamond surfaces and those with continuous diamond surfaces. Interrupted surfaces, like the DMT Duo-Sharp line, contain holes to capture metal filings, ensuring efficient cutting and economical usage. On the other hand, continuous surfaces, exemplified by the DMT Dia-Sharp line, are preferred for sharpening tools with pointed edges that might get caught in the recesses of interrupted surfaces.

Diamond sharpening stones excel in several aspects, including unmatched cutting speed, prolonged durability—especially those with mono-crystalline diamonds—and exceptional flatness retention over their lifespan. They are also incredibly easy to maintain, requiring simple drying after use.

Available in grits ranging from 220 to 1200, diamond stones offer a wide selection for various sharpening needs. However, for finer grits beyond 1200, complementing diamond stones with water stones for polishing is common practice.

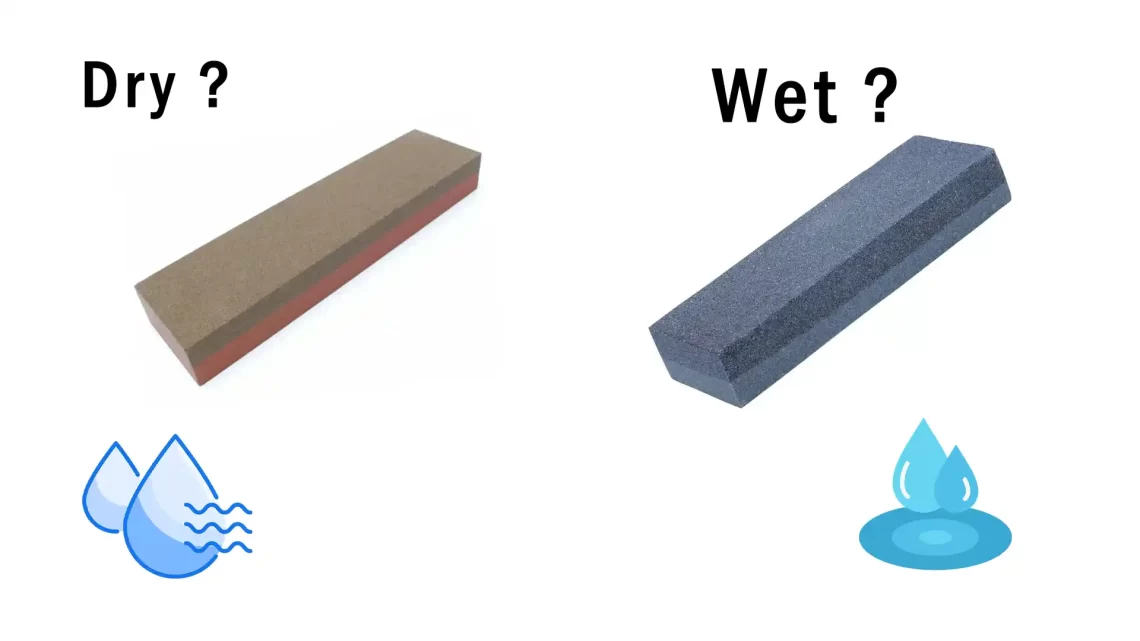

Oil Stones

Oil stones, a traditional choice for sharpening, are characterized by their hardness and reliance on oil for swarf removal and preventing clogging. Made from materials like Novaculite, Aluminum Oxide, or Silicon Carbide, oil stones offer distinct advantages in sharpening.

Natural oil stones, such as Arkansas Stones, derived from Novaculite, provide a polished edge but tend to cut more slowly compared to man-made alternatives. The grading system for these stones categorizes them based on density and the finish they impart on blades, with finer grades being more expensive.

Man-made oil stones, like Aluminum Oxide stones such as the Norton India Stones, offer fast cutting capabilities and produce fine edges on tools and knives. They are often used alongside Arkansas Stones to cover a broader grit range, with options labeled fine, medium, and coarse.

Silicon Carbide stones, like the Norton Crystolon Stones, stand out for their rapid cutting properties, making them ideal for initial coarse sharpening. While they may not achieve the fine edge of Arkansas or Aluminum Oxide stones, their efficiency and affordability make them a popular choice for many.

In conclusion, understanding the differences in sharpening stone materials is crucial for achieving optimal sharpening results. Water stones offer rapid cutting and a wide range of grits, while diamond stones excel in speed, durability, and flatness retention. Oil stones, whether natural or man-made, provide varying degrees of cutting performance and are valued for their affordability. By selecting the appropriate material based on sharpening needs and preferences, users can ensure efficient and effective sharpening of their tools and knives.