What is a knife sharpening stone?

A knife sharpening stone, such as the Naniwa Chosera or Shark Brand stones, is a crucial tool for knife maintenance, honing, and sharpening. These Japanese whetstones come in various grits, from coarse to fine, like the #400 to #10,000, providing options for different knife sharpening needs. Diamond stones are also available for efficient sharpening. To ensure optimal performance, regularly flatten the stones using a flattening stone or lapping plate like the Jende Glass Lapping Plate. Proper maintenance includes soaking the stones before use, letting them air dry, and storing them dry.

What is a Whetstone & How is it Made?

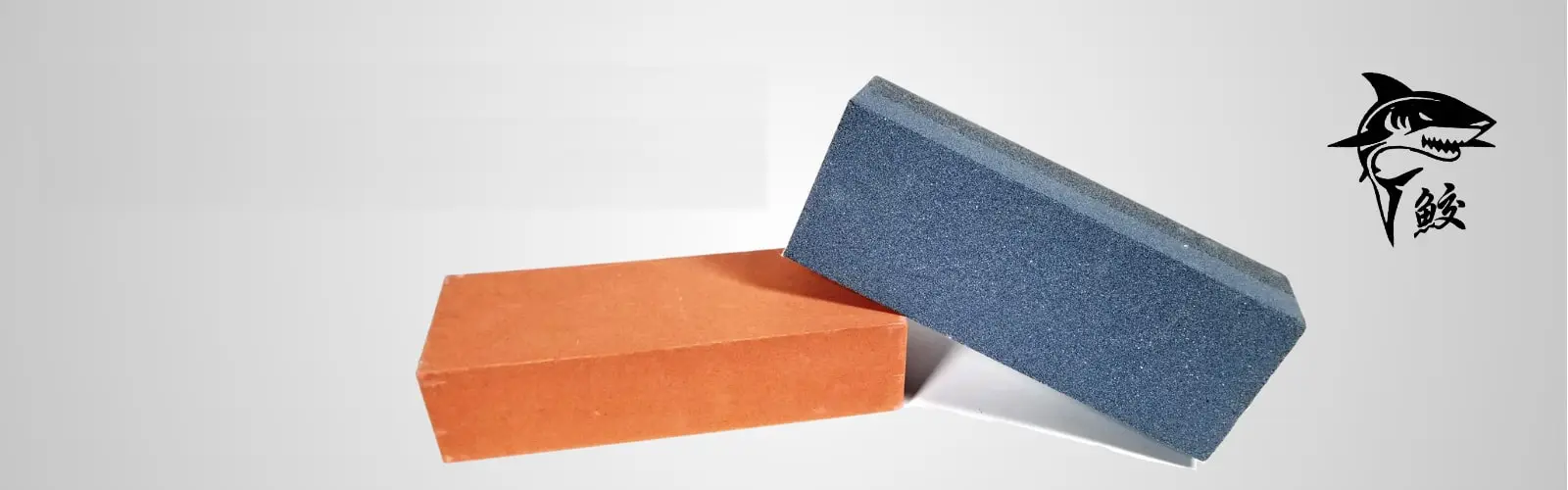

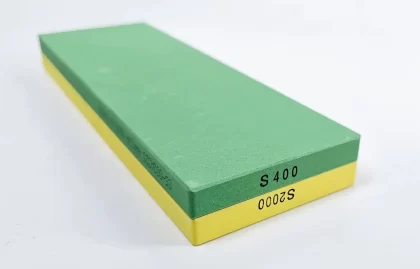

A whetstone, like the Naniwa and Shark Brand stones, is a tool used for sharpening knives. It’s made of materials like aluminum oxide or silicon carbide, shaped into a rectangular block. The surface has two sides with different grits, such as #400 and #2,000, for various sharpening needs. To use, soak the stone in water before sharpening, then air dry it afterward. Regular maintenance involves flattening stone with a lapping plate and storing it dry.

What are Naniwa super stones made of?

Naniwa Stones are made of aluminum oxide abrasive material. They feature a dual-sided design, with one side typically coarser, around #400 grit, and the other finer, around #2,000 grit. These stones are specifically crafted for efficient knife maintenance and sharpening. To use them effectively, soak them in water before sharpening, and ensure they air dry after use. Regular maintenance involves flattening stone with a lapping plate and storing it dry.

Do Naniwa stones need to be soaked?

Yes, Naniwa stones, like other Japanese whetstones, require soaking before use. This helps ensure optimal sharpening performance. Soaking allows the stone’s abrasive material, such as aluminum oxide, to absorb water, which aids in lubrication during sharpening. For best results, soak the stone for a minute or two before use. After sharpening, let it air dry thoroughly before storing it dry. This soaking process is essential for maintaining the quality and effectiveness of Naniwa stones in knife sharpening.

what is a diamond lapping plate ?

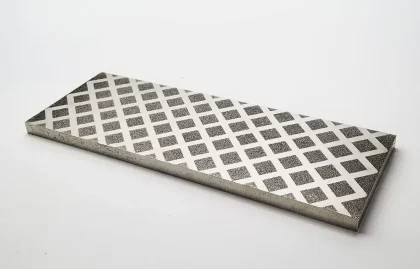

A diamond lapping plate is a flat surface made of solid metal, often 10mm thick, with a grid layout of diamond abrasive material, usually around 100 grit. It’s designed for flattening and maintaining the surface of sharpening stones, such as Naniwa stones. The channels between the diamond grits allow for slurry runoff, preventing the plate from loading up and ensuring minimal stiction on higher grit stones. This plate is crucial for keeping sharpening stones flat and clean over time, ensuring consistent sharpening performance.